We are doing pretty well with the preparation of our robots. Compared to the previous years, we have the mobile base for our first robot very early. But that is no surprise.

Indeed, we use the workshop of our school where we machine ourselves the pieces. I was trained to use a milling cutter. The machines we have are quite old and have a least 40 years. Those are not numeric, but manual, and I must say it is a pretty unusual and nice feeling to manipulate them. Of course, we have a lot of safety rules to obey, in order to prevent accidents. This year, due to all the renovations throughout the campus, the workshop must move out and settle at the other end of the campus. That means moving the very heavy equipment they have and it sounds like a real nightmare of organization. Anyway, they closed the workshop in January (a few weeks earlier than what we were initally told, bad surprise ...) so we had to have most of the job done by then. Indeed, almost every piece for our principal robot is done, and we have begun to build it. But for the second robot, we don't have anything ready. We haven't made the CATIA model yet, but we will do it soon. And since we won't be able to machine the pieces, we will probably print them with a 3D printer and have an almost-all-plastic robot. For the job it will do, it doesn't pose any problem.

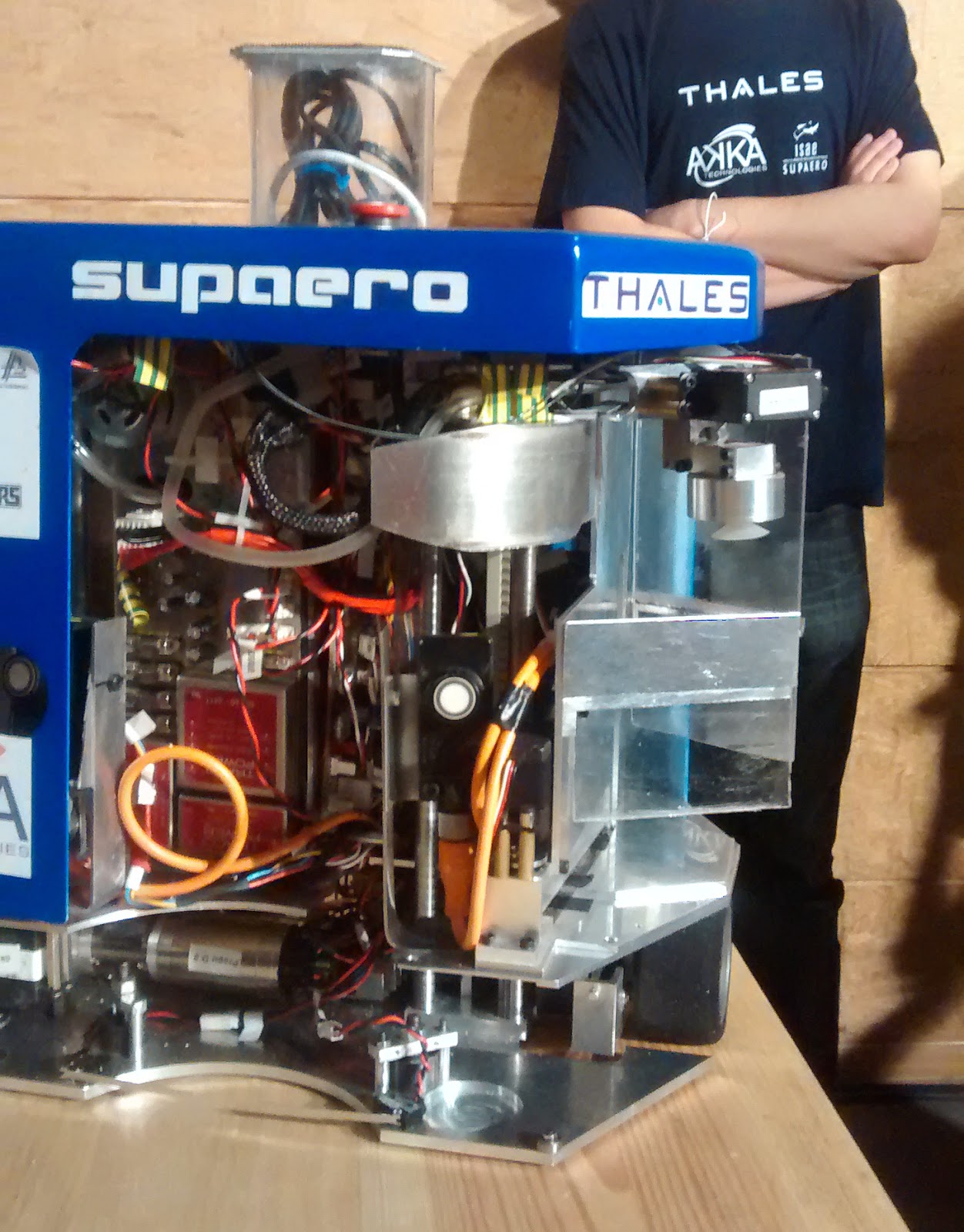

So, for now, our main robot looks like this :

It is lacking a lot of its parts. In fact, it has just the necessary to be able to move. We had to improvise to make everything hold together, so yes, there is a lot of tape. We are waiting for some components to arrive, in order to continue to build the robot. But with this version, I could already make a first automatic control. We use a PID controller. Here, you can see the robot turning 90° :

I didn't tuned the odometry parameters, so the robot doesn't move in a straight line when asked to, but makes a slightly curved line. It is, for example, because we entered in the code a value for the odometry wheels, which is not exact, and the two wheels may have slightly different diameters. So while both wheels think they went over the same distance, one did in fact travel a longer path, hence the curved line. This type of uncertainties cause errors that happen every time and that we can predict, so we call them systematic errors. There a few ways to correct them, and I will explain how we do it when it will be done. But for now, I am waiting so that I will not have to tune the parameters too many times, because each time the robots changes (the global mass, the mass center ...), they have to be set again. Still, don't worry, I still have a lot of things to do, including coding the functions that will allow the robot to move its actuators.